Did you know that most faults in solar panels originate during the manufacturing process? Tiny defects, unnoticed by the naked eye, can significantly impact the efficiency and longevity of the panels. Ensuring top-notch quality control during production is crucial to delivering reliable and high-performing solar panels.

One of the leading Solar PV manufacturers in India, IB Solar, has perfected the art of manufacturing high-quality solar panels by implementing rigorous quality control measures at every stage of production. Join us as we walk you through the meticulous steps taken at IB Solar’s state-of-the-art 500 MW manufacturing site in Noida to ensure each panel meets the highest standards of excellence.

1. Cell Testing for Power

The journey of a solar panel begins with rigorous cell testing. Each solar cell undergoes a detailed power output assessment using advanced testing equipment. This step ensures that only cells with optimal efficiency and performance are selected for further processing, guaranteeing the highest energy conversion rates for our panels.

2. CCD Camera for Checking Cell Visual Defects

Next, we employ high-resolution CCD cameras to inspect each cell for visual defects. This automated process detects minute imperfections such as micro-cracks, discoloration, or other anomalies that could affect the panel’s performance. This stringent quality control measure ensures that only flawless cells proceed to the next stage.

3. String Level Inspection

During string-level inspection, solar cells are interconnected to form strings. Each string is carefully inspected to verify the integrity of the interconnections and to ensure there are no defects that could impact the panel’s efficiency. This step is crucial for maintaining the consistency and reliability of the final product.

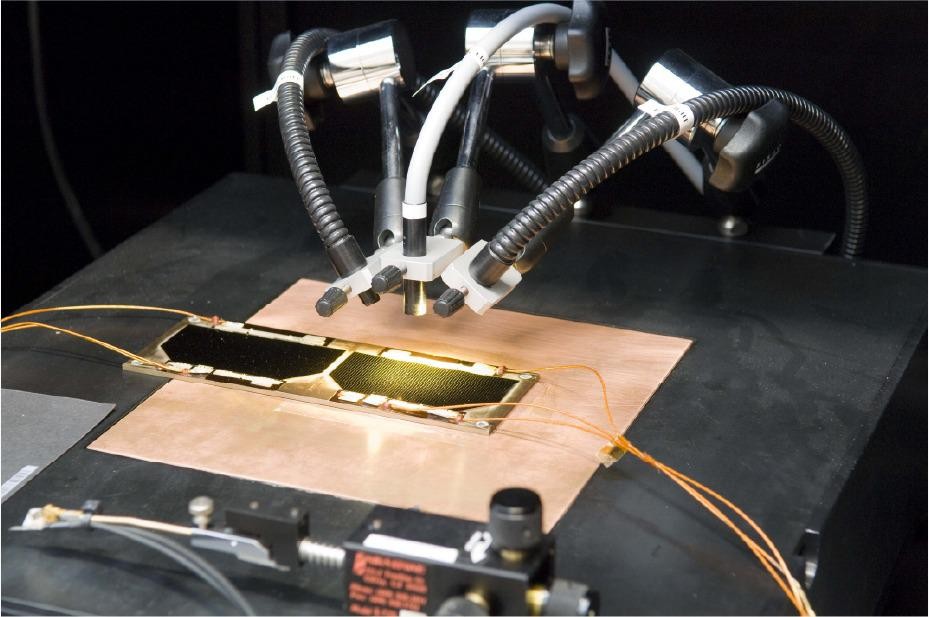

4. Pre-EL + Visual Inspection before Lamination

Before lamination, we conduct a pre-electroluminescence (Pre-EL) test along with a thorough visual inspection. The Pre-EL test uses specialized imaging technology to identify any hidden micro-cracks or defects not visible to the naked eye. This ensures that any potential issues are addressed before the critical lamination process.

5. 90-Degree Inspection Table after Lamination

Post-lamination, each panel is examined on a 90-degree inspection table. This allows our technicians to scrutinize the panel from various angles, ensuring the lamination process has been flawlessly executed. Any anomalies are rectified to maintain the high standards expected of IB Solar products.

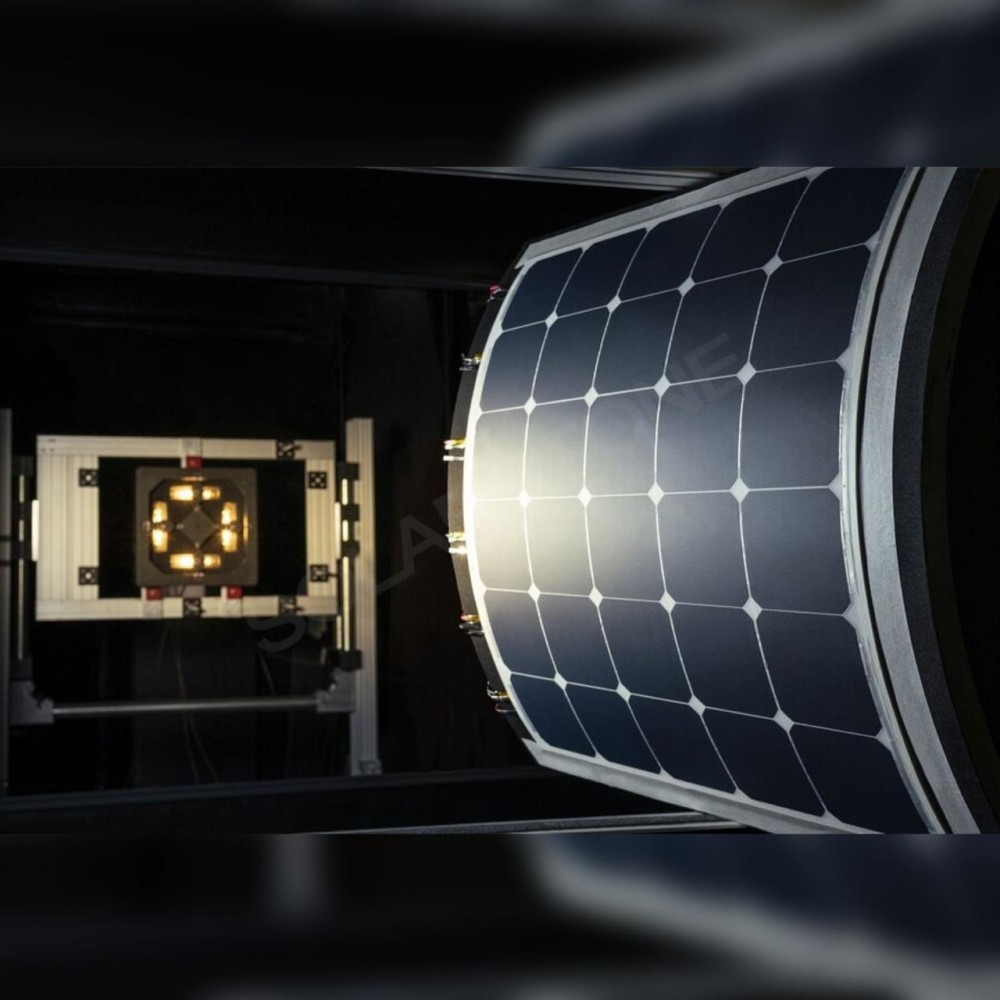

6. Sun Simulation to Check Solar Panel Power Output

To simulate real-world conditions, we use sun simulators to test the power output of each panel. This step mimics the solar spectrum to accurately measure the panel’s efficiency and performance. Only panels that meet our stringent power output criteria move forward in the production process.

7. Hi-Pot Test to Check IR and Leakage Current

Safety and reliability are paramount. The Hi-Pot test (High Potential test) assesses the panel’s insulation resistance (IR) and checks for leakage current. This ensures that the panels can operate safely under high voltage conditions, preventing any potential electrical hazards.

8. Post Lamination EL

Finally, a post-lamination electroluminescence (EL) test is conducted. This final inspection identifies any micro-cracks or defects that may have developed during lamination. By catching and addressing these issues at this stage, we ensure the structural and functional integrity of each solar panel.

Conclusion

At IB Solar, we are dedicated to delivering top-quality solar panels through a meticulous and rigorous production process. Our commitment to quality is reflected in the multiple layers of testing and inspection that each panel undergoes. As one of the few top manufacturers in India, we take special care to ensure that our products not only meet but exceed industry standards, providing you with efficient, reliable, and long-lasting solar energy solutions.

For more information on our products and to explore how IB Solar can help you harness the power of the sun, visit our website or contact our expert team today!

Recent Comments